Neuronix empowers manufacturers to eliminate manual inefficiencies with intelligent automation, delivering faster, smarter and higher-quality production at scale.

Manual inspection often misses micro-defects, and creates product variability.

Human-dependent checks slow output and increase operational costs.

Isolated systems limit real-time visibility, traceability, and production control.

Legacy infrastructure cannot adapt to growing product complexity.

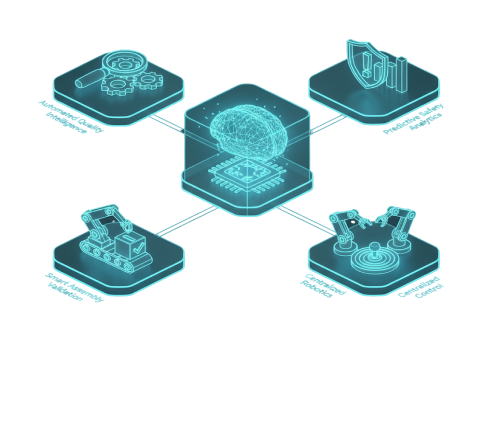

AI-powered vision that identifies and classifies defects instantly for zero-defect manufacturing.

Continuous monitoring with early alerts to prevent safety hazards and downtime.

Automated verification and compliance checks to maintain assembly accuracy and consistency.

Synchronizes robotic fleets and industrial equipment for maximum efficiency across facilities.